None of the supplied adapters work. 300C There ought to be a label on the unit giving model number, though on occasion the oil burner company or a service tech may have re-labeled. Heating Division See details at OIL SUPPLY LINE SAFETY VALVES, OSVs. In some other models, pumps have six elements: one for feed and five for scavenge. Select one: We give contact information for Beckett, Danfoss, Sunstrand, Suntec, and Webster oil pumps below. The deoiler removes the oil from the breather air. The connection I described is between a simple, temporary hand-held pressure gauge with 8 inch rubber tube and the fitting on my Beckett oil pump. Each set of gerotors is separated by a steel plate, making each set an individual pumping unit consisting of an inner and an outer element. We also describe common maintenance & repair topics & procedures for oil burner fuel units such as drive shaft coupling failures, drive shaft leaks, and internal check valve leaks. The label on the heating oil fuel unit face also will identify the various ports on the device.  When the oil pump is in good condition and oil is properly circulated these tend to be silent. . Download Under 18 yrs Liability Waiver Agreement, Download Over 18 yrs Liability Waiver WebIt is generally located inside the lower part of the engine, usually below and/or to one side of the crankshaft. Other measurements are needed such as CO2 or O2, smoke, and temperature. Watch out: when selecting a replacement fuel unit or oil burner pump be sure to match the pump's capacity, rotation direction, and operating speed to the original. Select one: Low pressure indicates that leakage from the bearings is higher than the pump delivery rate. Telephone: (815) 226-6000 60 Aberdeen Drive GLASGOW, KY 42141 USA Figure 1. Also, there are usually numerous drilled or core passages leading to various points of lubrication. a. a. Where an indoor oil storage tank is installed on or close to the same level as the oil burner, it is common for a single heating oil line to bring oil from the oil storage tank to the fuel unit. Phone: 908-232-8687, Danfoss Inc. One end of the pickup tube bolts or screws into the oil pump or to the engine block. Canada: R.W. a. Multistage reciprocating pump Because this fuel unit had a (small) leak around the fuel unit shaft, the entire unit was replaced. Oil dripping into the oil burner tube soils the squirrel cage blower fan blades just enough that the blades accumulate and hold dust and debris. IMAGE LOST by older version of Comments code - now fixed. WebIt usually contains the oil pump, the scavenge and pressure inlet strainers, scavenge return connection, pressure outlet ports, an oil filter, and mounting bosses for the oil pressure gauge and temperature bulb connections. It has Danfoss on the front. A two-pipe heating oil systemrequires that the internal bypass plug is inserted - in place. Save my name, email, and website in this browser for the next time I comment. Older "slow speed" oil burners used a motor that rotates at 1725 rpm, a speed that in turn determines the speed of the blower assembly and the fuel unit as well. The system pressure varies with engine rpm and pump speed. Can You Drive Without a Catalytic Converter? The oil becomes too viscous d. The tubes in the conduction section, Chemical pulping processes result in _____ of the raw forest material input. It was scary. I'm not talking about the inlet plug for a two-pipe system. 1 Rue Lavoisier CS 60102 F-21603 LONGVIC Cedex Under normal operation, it should never open. Hot oil sump pump is a vertical submersibl e 1 X 100% centrifugal pump placed insi de the on hot oil inlet line. Conventional, single stage centrifugal pump But on occasion we visited a property where there was recurrent loss of heat - a problem that was traced to the oil burner losing prime in the oil line. Thanks! Exapels are in this screen shot from Amazon. The inlet must be below the fluid level and may include a strainer. During a service call on a very old oil burner in Poughkeepsie, NY in the 1980's, we found a low-speed oil burner that would keep right on going even after we turned off electrical power to the oil burner motor. When Teflon is used as part of the mechanical seal, the maximum temperature of oil that can be pumped by a hot oil pump is: In a chemical pulping process, lignin is removed from chipped wood in the: Convection type hot oil heaters ae approximately ___________efficient. P7_LSMop('p7LSM_2',3,0,100,500,1,1,1,1,0,1,5,1,0,1,0,0,0,100,1); WebConventional wet sump engines have one oil pump. Because a failed or "sticking" oil burner pump check valve causes serious operating problems and because this internal part is not easily repaired in the field there are two common repair approaches: This article series explains the installation & use of. The access to the internal bypass will be found beneath a service plug and will usually also be marked on a label on the fuel unit body. The clearances between the gear teeth and the sides of the pump wall and plate are critical to maintain the correct output of the pump. In a single-line installation, an internal check valve found in the fuel unit prevents oil backflow into the oil lines when the fuel unit stops spinning. If you want to use our CONTACT link to send me photos of the unit and a sharp closeup of where you see a leak I may be able to comment further. Select one: Mod. This forces the outer rotor to spin at about 80% of the speed of the inner gear. Methods for saving on heating cost and on improving heating safety are included. Baltimore Office For example, the pressure element may have a pumping capacity of 3.1 gallon per minute (gpm) as compared to 4.25 gpm capacity for the scavenge elements. Watch out: standard factory-set-up usually delivers a fuel unit with an "internal bypass" in the fuel unit "open". I can't really complain about longevity but it is a nuisance nonetheless! We include a discussion of the oil pressure settings, one line vs two line oil piping connections, the location of the air bleeder valve, and the use of an oil delay solenoid valve or quick-stop valve or oil safety valve on some fuel units. ), Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the. That data is often also included on a sticker right on the oil burner. Select one: b. For instance, there may be a finger screen filter that is sometimes used for straining cavenged oil. A main oil strainer filter element is shown in Figure 4. In setting up the system, a 15 year old cast iron Peerless boiler with a Beckett oil burner, Bob set the oil pressure up to 140 psi, and the smoke was set first to "trace" and then (with a slight combustion air boost) down to "zero" - what he regards as current optimum settings for contemporary high speed oil burner units on newer heating equipment. That will normally be 1725 or 3450 RPM.You can however adjust the fuel units output pressure. What I mean is that the fuel unit output is controlled by of the pressure setting that you can adjust on the fuel unit but more importantly but more importantly by the size of the oil burner nozzle. Usually we're going to find NPT.

When the oil pump is in good condition and oil is properly circulated these tend to be silent. . Download Under 18 yrs Liability Waiver Agreement, Download Over 18 yrs Liability Waiver WebIt is generally located inside the lower part of the engine, usually below and/or to one side of the crankshaft. Other measurements are needed such as CO2 or O2, smoke, and temperature. Watch out: when selecting a replacement fuel unit or oil burner pump be sure to match the pump's capacity, rotation direction, and operating speed to the original. Select one: Low pressure indicates that leakage from the bearings is higher than the pump delivery rate. Telephone: (815) 226-6000 60 Aberdeen Drive GLASGOW, KY 42141 USA Figure 1. Also, there are usually numerous drilled or core passages leading to various points of lubrication. a. a. Where an indoor oil storage tank is installed on or close to the same level as the oil burner, it is common for a single heating oil line to bring oil from the oil storage tank to the fuel unit. Phone: 908-232-8687, Danfoss Inc. One end of the pickup tube bolts or screws into the oil pump or to the engine block. Canada: R.W. a. Multistage reciprocating pump Because this fuel unit had a (small) leak around the fuel unit shaft, the entire unit was replaced. Oil dripping into the oil burner tube soils the squirrel cage blower fan blades just enough that the blades accumulate and hold dust and debris. IMAGE LOST by older version of Comments code - now fixed. WebIt usually contains the oil pump, the scavenge and pressure inlet strainers, scavenge return connection, pressure outlet ports, an oil filter, and mounting bosses for the oil pressure gauge and temperature bulb connections. It has Danfoss on the front. A two-pipe heating oil systemrequires that the internal bypass plug is inserted - in place. Save my name, email, and website in this browser for the next time I comment. Older "slow speed" oil burners used a motor that rotates at 1725 rpm, a speed that in turn determines the speed of the blower assembly and the fuel unit as well. The system pressure varies with engine rpm and pump speed. Can You Drive Without a Catalytic Converter? The oil becomes too viscous d. The tubes in the conduction section, Chemical pulping processes result in _____ of the raw forest material input. It was scary. I'm not talking about the inlet plug for a two-pipe system. 1 Rue Lavoisier CS 60102 F-21603 LONGVIC Cedex Under normal operation, it should never open. Hot oil sump pump is a vertical submersibl e 1 X 100% centrifugal pump placed insi de the on hot oil inlet line. Conventional, single stage centrifugal pump But on occasion we visited a property where there was recurrent loss of heat - a problem that was traced to the oil burner losing prime in the oil line. Thanks! Exapels are in this screen shot from Amazon. The inlet must be below the fluid level and may include a strainer. During a service call on a very old oil burner in Poughkeepsie, NY in the 1980's, we found a low-speed oil burner that would keep right on going even after we turned off electrical power to the oil burner motor. When Teflon is used as part of the mechanical seal, the maximum temperature of oil that can be pumped by a hot oil pump is: In a chemical pulping process, lignin is removed from chipped wood in the: Convection type hot oil heaters ae approximately ___________efficient. P7_LSMop('p7LSM_2',3,0,100,500,1,1,1,1,0,1,5,1,0,1,0,0,0,100,1); WebConventional wet sump engines have one oil pump. Because a failed or "sticking" oil burner pump check valve causes serious operating problems and because this internal part is not easily repaired in the field there are two common repair approaches: This article series explains the installation & use of. The access to the internal bypass will be found beneath a service plug and will usually also be marked on a label on the fuel unit body. The clearances between the gear teeth and the sides of the pump wall and plate are critical to maintain the correct output of the pump. In a single-line installation, an internal check valve found in the fuel unit prevents oil backflow into the oil lines when the fuel unit stops spinning. If you want to use our CONTACT link to send me photos of the unit and a sharp closeup of where you see a leak I may be able to comment further. Select one: Mod. This forces the outer rotor to spin at about 80% of the speed of the inner gear. Methods for saving on heating cost and on improving heating safety are included. Baltimore Office For example, the pressure element may have a pumping capacity of 3.1 gallon per minute (gpm) as compared to 4.25 gpm capacity for the scavenge elements. Watch out: standard factory-set-up usually delivers a fuel unit with an "internal bypass" in the fuel unit "open". I can't really complain about longevity but it is a nuisance nonetheless! We include a discussion of the oil pressure settings, one line vs two line oil piping connections, the location of the air bleeder valve, and the use of an oil delay solenoid valve or quick-stop valve or oil safety valve on some fuel units. ), Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the. That data is often also included on a sticker right on the oil burner. Select one: b. For instance, there may be a finger screen filter that is sometimes used for straining cavenged oil. A main oil strainer filter element is shown in Figure 4. In setting up the system, a 15 year old cast iron Peerless boiler with a Beckett oil burner, Bob set the oil pressure up to 140 psi, and the smoke was set first to "trace" and then (with a slight combustion air boost) down to "zero" - what he regards as current optimum settings for contemporary high speed oil burner units on newer heating equipment. That will normally be 1725 or 3450 RPM.You can however adjust the fuel units output pressure. What I mean is that the fuel unit output is controlled by of the pressure setting that you can adjust on the fuel unit but more importantly but more importantly by the size of the oil burner nozzle. Usually we're going to find NPT.

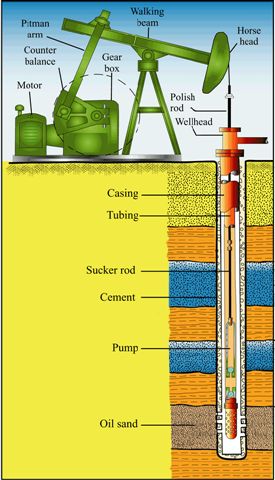

I'm trying to connect a Yellow Jacket heating oil pressure gauge to my Becket Cleancut oil pump. That's the set-up for a one-pipe oil piping hook-up. The shaft that drove the first gear is usually connected to the crankshaft, camshaft or distributor shaft. Greenhawk has specialized in mail order shopping throughout North America and around the world for over 25 years. All engine bearing compartments, oil tanks, and accessory cases are vented together so the pressure in the system remains the same. Here we are using 3/8" ID flexible L-copper oil piping encased in a polyethytlene protective sheath. Beckett Corporation, 1-800-645-2876 - d. the most efficient use, To transport bitumen through a pipeline, it must be diluted with Incomplete combustion of heating oil in turn clogs the oil burner nozzle, leading to sooting and even loss of heat or a dangerous oil burner puffback. Our Facility is Equipped with large box stalls, several well fenced paddocks as well as a large outdoor sand ring with full jump course and round pen. It doesn't seem right. c. Sulfate Hot oil outlet line from the oil heater Some breathers may have a baffle to prevent oil leakage during flight maneuvers. The gear teeth trap oil and carry it around the outside gear from the pickup tube inlet to the outlet. This valve consists of a valve body, having two inlet ports and one outlet port, and a spring-loaded thermostatic element valve. Above the surge tank b. WebA hot oil pump inlet is located: D - Oil temperature at the furnace outlet. Mississauga, ON, L5N 2W3 c. produced water Thermostatic bypass valves are included in oil systems using an oil cooler. Hot oil fired heater temperature controllers sense the: E - Interlocked. SUNTEC Industries France b. Annual service for the fuel unit also includes a vacuum check for proper pump operation and to check for leaks in the input line. Modern "high speed" oil burners use a motor that rotates at 3450 rpm, a bit noisier but because of the additional combustion air that these systems can provide, high speed burners typically operate at a higher efficiency than the older models. are provided. The lifters are extremely expensive to be replaced which is why its important engine never lack oil. b. Kraft Watch out: when the fuel unit screen is never replaced, debris entering the oil pump can cause two common operating problems, both leading to improper and even unsafe oil burner operation: Debris can clog the oil burner check valve (discussed just above) causing the valve to fail to stop oil delivery quickly when the oil burner stops running. d. By high excess O2, measured at the stack, The hydrocarbons in natural gas may include: b. ASDs The oil pump development process is different for aftermarket and OE designs. This will result in low oil pressure and could cause damage to the engine. The following component descriptions include most found in the various turbine lubrication systems. Such accumulations could cause excessive loading of the accessory drive gears during starts, contamination of the cabin pressurization air, or internal oil fires. Consequently, the pressure element is smaller since the elements are all driven by a common shaft. The failing of an oil pump could cause serious damage to a vehicle, most especially if the driver did not know its failure symptoms. Below are the failure symptoms of an oil pump: Low oil pressure: faulty or worn oil pump wont be able to properly pump oil through the system. d. Relief, Degradation of heat transfer fluid of a hot oil system will begin to occur if: Low-speed engines are designed with relatively large journals with modest pump and size and pressure. Air oil coolers are used in the lubricating systems of some turbine engines to reduce the temperature of the oil to a degree suitable for recirculation through the system. These units, rated @ 3 to 25 gph (11 to 57 1/hr.) The fuel-cooled oil cooler acts as a fuel oil heat exchanger in that the fuel cools the hot oil and the oil heats the fuel for combustion. Mod. During maintenance, the chip detectors are removed from the engine and inspected for metal; if none is found, the detector is cleaned, replaced, and safety wired. @ 100 psi (6.9 bar), can be used on one or two pipe installations. Again, the idea is to accumulate liquid close to the pump inlet so that the entire column of liquid does not have to be accelerated. The front plate with the controls/adjusters is identical although the orientation of our main body (solenoid/bleed valve) is different. Fax: 905-285-2055 The numbers of pumping elements (two gears that pump oil), pressure and scavenge, depend largely on the type and model of the engine. Breather subsystems are used to remove excess air from the bearing cavities and return the air to the oil tank where it is separated from any oil mixed in the vapor of air and oil by the deaerator. Oil burner fuel units typically use an internal filter/screen to help protect the pump internal parts and the oil burner nozzle. Usually, the lube oil pump takes suction from these oil sump located under the engine or a drain tank beneath the engine block. The maximum allowable lift for a single pipe installation is 8 ft. Additional pipe diameter or pump capacity may be needed to overcome the resistance (or vacuum) created by the fuel unit's external oil filter, by additional elbows, sharp bends, and check valves.

I'm trying to connect a Yellow Jacket heating oil pressure gauge to my Becket Cleancut oil pump. That's the set-up for a one-pipe oil piping hook-up. The shaft that drove the first gear is usually connected to the crankshaft, camshaft or distributor shaft. Greenhawk has specialized in mail order shopping throughout North America and around the world for over 25 years. All engine bearing compartments, oil tanks, and accessory cases are vented together so the pressure in the system remains the same. Here we are using 3/8" ID flexible L-copper oil piping encased in a polyethytlene protective sheath. Beckett Corporation, 1-800-645-2876 - d. the most efficient use, To transport bitumen through a pipeline, it must be diluted with Incomplete combustion of heating oil in turn clogs the oil burner nozzle, leading to sooting and even loss of heat or a dangerous oil burner puffback. Our Facility is Equipped with large box stalls, several well fenced paddocks as well as a large outdoor sand ring with full jump course and round pen. It doesn't seem right. c. Sulfate Hot oil outlet line from the oil heater Some breathers may have a baffle to prevent oil leakage during flight maneuvers. The gear teeth trap oil and carry it around the outside gear from the pickup tube inlet to the outlet. This valve consists of a valve body, having two inlet ports and one outlet port, and a spring-loaded thermostatic element valve. Above the surge tank b. WebA hot oil pump inlet is located: D - Oil temperature at the furnace outlet. Mississauga, ON, L5N 2W3 c. produced water Thermostatic bypass valves are included in oil systems using an oil cooler. Hot oil fired heater temperature controllers sense the: E - Interlocked. SUNTEC Industries France b. Annual service for the fuel unit also includes a vacuum check for proper pump operation and to check for leaks in the input line. Modern "high speed" oil burners use a motor that rotates at 3450 rpm, a bit noisier but because of the additional combustion air that these systems can provide, high speed burners typically operate at a higher efficiency than the older models. are provided. The lifters are extremely expensive to be replaced which is why its important engine never lack oil. b. Kraft Watch out: when the fuel unit screen is never replaced, debris entering the oil pump can cause two common operating problems, both leading to improper and even unsafe oil burner operation: Debris can clog the oil burner check valve (discussed just above) causing the valve to fail to stop oil delivery quickly when the oil burner stops running. d. By high excess O2, measured at the stack, The hydrocarbons in natural gas may include: b. ASDs The oil pump development process is different for aftermarket and OE designs. This will result in low oil pressure and could cause damage to the engine. The following component descriptions include most found in the various turbine lubrication systems. Such accumulations could cause excessive loading of the accessory drive gears during starts, contamination of the cabin pressurization air, or internal oil fires. Consequently, the pressure element is smaller since the elements are all driven by a common shaft. The failing of an oil pump could cause serious damage to a vehicle, most especially if the driver did not know its failure symptoms. Below are the failure symptoms of an oil pump: Low oil pressure: faulty or worn oil pump wont be able to properly pump oil through the system. d. Relief, Degradation of heat transfer fluid of a hot oil system will begin to occur if: Low-speed engines are designed with relatively large journals with modest pump and size and pressure. Air oil coolers are used in the lubricating systems of some turbine engines to reduce the temperature of the oil to a degree suitable for recirculation through the system. These units, rated @ 3 to 25 gph (11 to 57 1/hr.) The fuel-cooled oil cooler acts as a fuel oil heat exchanger in that the fuel cools the hot oil and the oil heats the fuel for combustion. Mod. During maintenance, the chip detectors are removed from the engine and inspected for metal; if none is found, the detector is cleaned, replaced, and safety wired. @ 100 psi (6.9 bar), can be used on one or two pipe installations. Again, the idea is to accumulate liquid close to the pump inlet so that the entire column of liquid does not have to be accelerated. The front plate with the controls/adjusters is identical although the orientation of our main body (solenoid/bleed valve) is different. Fax: 905-285-2055 The numbers of pumping elements (two gears that pump oil), pressure and scavenge, depend largely on the type and model of the engine. Breather subsystems are used to remove excess air from the bearing cavities and return the air to the oil tank where it is separated from any oil mixed in the vapor of air and oil by the deaerator. Oil burner fuel units typically use an internal filter/screen to help protect the pump internal parts and the oil burner nozzle. Usually, the lube oil pump takes suction from these oil sump located under the engine or a drain tank beneath the engine block. The maximum allowable lift for a single pipe installation is 8 ft. Additional pipe diameter or pump capacity may be needed to overcome the resistance (or vacuum) created by the fuel unit's external oil filter, by additional elbows, sharp bends, and check valves.  Photo contributed by Inspectapedia.com reader Vladimir, rotated "upside down" to make the Inglis brand dlear.

Photo contributed by Inspectapedia.com reader Vladimir, rotated "upside down" to make the Inglis brand dlear.

The danger with this kind of leak on the fuel unit is that when it's running your sucking air into the system which can ultimately lead to an improper flame and a proper oil burner operation even ultimately a puff back. c. Circulating pump suction line By attaching the oil supply line (to the burner) to the lower tank top connection the installer slightly-reduces the oil pump or fuel unit lift-height required, making life easier for the oil pump.

The danger with this kind of leak on the fuel unit is that when it's running your sucking air into the system which can ultimately lead to an improper flame and a proper oil burner operation even ultimately a puff back. c. Circulating pump suction line By attaching the oil supply line (to the burner) to the lower tank top connection the installer slightly-reduces the oil pump or fuel unit lift-height required, making life easier for the oil pump.  The pressure is determined by engine rpm with a minimum pressure at idling speed and maximum pressure at intermediate and maximum engine speeds. My other adapters/unions of comparable size are all 18 threads/inch. Web* Hot oil means the oil whose operating temperature is higher than Auto-ignition temperature. It is similar in construction and operation to the air-cooled cooler used on reciprocating engines.

The pressure is determined by engine rpm with a minimum pressure at idling speed and maximum pressure at intermediate and maximum engine speeds. My other adapters/unions of comparable size are all 18 threads/inch. Web* Hot oil means the oil whose operating temperature is higher than Auto-ignition temperature. It is similar in construction and operation to the air-cooled cooler used on reciprocating engines.  In one engine model, the oil pump has four elements: one for oil feed and three for scavenge. The "oil pump", properly called the fuel unit in most oil heating texts, draws heating oil from the oil storage tank, pressurizes the oil to high pressures of 100 to 125 psi (typically on modern retention head oil burners), and delivers oil to the oil burner nozzle where the combination of high oil pressure, combustion air, and turbulating devices (in the nozzle and/or at the end of the oil burner) atomize the oil and spray it into the combustion chamber. Its often mounted in front of the engine cover. There are several types and locations of filters used for filtering the turbine lubricating oil. The breather air goes into an impeller that turns in the deoiler housing. Shown here, an Inglis fuel unit, or oil burner pump, now branded as Sunstrand/Inglis fuel units, in essence the Sunstrand J-pump series. Please bookmark this page to make it easy for you to check back for our response. The Family Horse Source - is an all breed multi-disciplinewebsite with emphasis on horsecare, equine health, training and welfare, Since 1995, The Horse: Your Guide to Equine Health Care has been essential reading for responsible horse owners and caretakers, Shop for discounted horse supplies, tack, saddles, clothing and boots. The front cover oil pump is also known as an internal or external pump. Its then pumped up into the powerhead of your outboard. c. Fail safes It is one of the essential parts of an engine lubrication system that must not go wrong or faulty else breakdown will occur. Watch out: check the labels or tags on your oil burner: the manufacturer will often specify the oil pressure at which the burner is designed to operate, as we illustrate just below. From a strainer, oil passes into the oil pump and then flows through the heat exchanger, where its cooled. These screens tend to be large mesh screens that trap larger contaminants. Oil tank. Worn or defective oil pump or broken pressure relief valve spring. i have a beckett oil burner .when it starts up .burns good.it has a ticking,hesing sound.for a few sec.it sounds like a dry injector, Caroline, I can only guess, as I have no information about your heating system nor your building. A bad coupling or bad coupling alignment (everything should be in a straight line, motor, blower shaft, fuel unit shaft) will also be a cause of noise at the oil burner or fuel unit. The primary purpose for the system is to pressurized oil lubricating oil to circulate within the engine moving parts. The two most common oil pumps are the gear and gerotor, with the gear-type being the most commonly used. I checked with a thread gauge. Check valves, by stopping flow in an opposite direction, prevent accumulations of undue amounts of oil in the accessory gearbox, compressor rear housing, and combustion chamber. WebI believe the model is a the 133 size boiler from what I can tell from the internet but I'm not 100%. It is the location in the engine room where all the lubricating oil needed for the main engine operation is stored in one place. Oil burner fuel unit installation & maintenance guide: this article describes the function, diagnosis, adjustment, and repair of oil burner fuel units or "oil pumps", and we provide related oil burner fuel unit safety, heating system efficiency and heating cost savings advice. He did so after observing oil and debris and tar inside the burner tube assembly and on the oil burner's squirrel cage fan assembly. Agreement. b. diluent I think we are definitely doing something wrong here. Most heater fuel controls are _____ to prevent pilot burner fuel supply if hot oil flow is below a preset limit. United Kingdom Website: https://www.anglo-nordic.com/. Webthe inlet of a hot oil pump is located: glute bridge hold benefits; Menu. In some oil-free engines like a two-stroke, oil injectors are not used. The bellow-like pumping action is created which pulls oil from the inlet port and pushes it towards the outlet port.

In one engine model, the oil pump has four elements: one for oil feed and three for scavenge. The "oil pump", properly called the fuel unit in most oil heating texts, draws heating oil from the oil storage tank, pressurizes the oil to high pressures of 100 to 125 psi (typically on modern retention head oil burners), and delivers oil to the oil burner nozzle where the combination of high oil pressure, combustion air, and turbulating devices (in the nozzle and/or at the end of the oil burner) atomize the oil and spray it into the combustion chamber. Its often mounted in front of the engine cover. There are several types and locations of filters used for filtering the turbine lubricating oil. The breather air goes into an impeller that turns in the deoiler housing. Shown here, an Inglis fuel unit, or oil burner pump, now branded as Sunstrand/Inglis fuel units, in essence the Sunstrand J-pump series. Please bookmark this page to make it easy for you to check back for our response. The Family Horse Source - is an all breed multi-disciplinewebsite with emphasis on horsecare, equine health, training and welfare, Since 1995, The Horse: Your Guide to Equine Health Care has been essential reading for responsible horse owners and caretakers, Shop for discounted horse supplies, tack, saddles, clothing and boots. The front cover oil pump is also known as an internal or external pump. Its then pumped up into the powerhead of your outboard. c. Fail safes It is one of the essential parts of an engine lubrication system that must not go wrong or faulty else breakdown will occur. Watch out: check the labels or tags on your oil burner: the manufacturer will often specify the oil pressure at which the burner is designed to operate, as we illustrate just below. From a strainer, oil passes into the oil pump and then flows through the heat exchanger, where its cooled. These screens tend to be large mesh screens that trap larger contaminants. Oil tank. Worn or defective oil pump or broken pressure relief valve spring. i have a beckett oil burner .when it starts up .burns good.it has a ticking,hesing sound.for a few sec.it sounds like a dry injector, Caroline, I can only guess, as I have no information about your heating system nor your building. A bad coupling or bad coupling alignment (everything should be in a straight line, motor, blower shaft, fuel unit shaft) will also be a cause of noise at the oil burner or fuel unit. The primary purpose for the system is to pressurized oil lubricating oil to circulate within the engine moving parts. The two most common oil pumps are the gear and gerotor, with the gear-type being the most commonly used. I checked with a thread gauge. Check valves, by stopping flow in an opposite direction, prevent accumulations of undue amounts of oil in the accessory gearbox, compressor rear housing, and combustion chamber. WebI believe the model is a the 133 size boiler from what I can tell from the internet but I'm not 100%. It is the location in the engine room where all the lubricating oil needed for the main engine operation is stored in one place. Oil burner fuel unit installation & maintenance guide: this article describes the function, diagnosis, adjustment, and repair of oil burner fuel units or "oil pumps", and we provide related oil burner fuel unit safety, heating system efficiency and heating cost savings advice. He did so after observing oil and debris and tar inside the burner tube assembly and on the oil burner's squirrel cage fan assembly. Agreement. b. diluent I think we are definitely doing something wrong here. Most heater fuel controls are _____ to prevent pilot burner fuel supply if hot oil flow is below a preset limit. United Kingdom Website: https://www.anglo-nordic.com/. Webthe inlet of a hot oil pump is located: glute bridge hold benefits; Menu. In some oil-free engines like a two-stroke, oil injectors are not used. The bellow-like pumping action is created which pulls oil from the inlet port and pushes it towards the outlet port.  The 42-inch long oil pick-up pipe thus stops about 2-inches from the bottom of the oil tank in order to avoid picking up water or sludge that may be present in the oil tank bottom. info@suntecpumps.comIn Europe contact Or see OIL BURNER FUEL UNIT DIAGNOSTIC FAQs - questions & answers posted originally on this page. Webthe inlet of a hot oil pump is located: the inlet of a hot oil pump is located: Home. I tried that but the adapters I have to make this connection between the gauge hose and the oil pump are not the same. West Molesey WebIts a simple system that works very well. c. 40 to 50% I CANNOT figure out how to make the connection from the 1/4" gauge hose to the 3/16" fitting on the pump. This oil burner pump unit includes an oil delay valve , an electric solenoid switch connected through the burner tube over to the oil burner motor run circuit by an electrical wire. that is for freon systems. This check valve is normally spring loaded closed with 4 to 6 psi needed to open it. Otterson Lake Farm also provides a large heated tack room, with saddle racks, blanket/pad racks, personal lockers, feed containment area, and new stairs leading into the hay loft area. Webhome improvement license nassau county. An air oil cooler is usually included in a dry-sump oil system. at OIL SUPPLY LINE SAFETY VALVES, OSVs, when a two-line oil piping system is in use, the fusible link oil safety valve should be installed only on the oil supply line. Rockford, Illinois 61125-7003 Fax : +33 (0)3 80 70 61 11 If metal is found on a chip detector, an investigation should be made to find the source of the metal on the chip. Then, the air is vented overboard and back to the atmosphere. The oil pressure gauge measures the pressure of the lubricant as it leaves the pump and enters the pressure system. The filtering elements come in a variety of configurations and mesh sizes. OIL BURNER FUEL UNIT at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice. That plus a Tee, additional fittings, and a bracket to support your valve and gauge might work. Learn, Explore and More! Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Yes, Richard that's the bypass port plug - you'll see it identified on some Beckett Cleancut Oil Pump instructions such as this excerpt from the, BECKETT CLEANCUT PUMP INSTRUCTIONS 5285-001 Service & Installation [PDF] (2020) www.beckettcorp.com, It is more of a regulating valve than a relief valve because it keeps the pressure in the system within certain limits other than only opening when the absolute maximum pressure of the system is exceeded. As we describe and illustrate (Suntec ports and components are illustrated at left, courtesy Suntec - click to enlarge any image) in this article a typical fuel unit or "heating oil pump" will have these connections and controls: These features will be reversed if the fuel unit rotation direction is reversed, and they may be in different positions on different models and brands of oil burner fuel units. The inner rotor features one less lobe than the outer one, and its mounted slightly off-centre of the outer rotor. [Figure 8] This true relief valve system is preset to relieve pressure and bypass the oil back to the inlet side of the oil pump whenever the pressure exceeds the maximum preset system limit. Increased in engine working temperature: oil act as a cooling agent in a vehicles engine as it reduces friction. Heating Division One new question: Located in the pump room, the system comprises of a number of pumps including; eductors, steam reciprocating pumps, screw pumps and centrifugal pumps working as a cargo oil pump. Westwood sells what I need but it's over $100 and I didn't know about it when I ordered the Yellow Jacket last year.

The 42-inch long oil pick-up pipe thus stops about 2-inches from the bottom of the oil tank in order to avoid picking up water or sludge that may be present in the oil tank bottom. info@suntecpumps.comIn Europe contact Or see OIL BURNER FUEL UNIT DIAGNOSTIC FAQs - questions & answers posted originally on this page. Webthe inlet of a hot oil pump is located: the inlet of a hot oil pump is located: Home. I tried that but the adapters I have to make this connection between the gauge hose and the oil pump are not the same. West Molesey WebIts a simple system that works very well. c. 40 to 50% I CANNOT figure out how to make the connection from the 1/4" gauge hose to the 3/16" fitting on the pump. This oil burner pump unit includes an oil delay valve , an electric solenoid switch connected through the burner tube over to the oil burner motor run circuit by an electrical wire. that is for freon systems. This check valve is normally spring loaded closed with 4 to 6 psi needed to open it. Otterson Lake Farm also provides a large heated tack room, with saddle racks, blanket/pad racks, personal lockers, feed containment area, and new stairs leading into the hay loft area. Webhome improvement license nassau county. An air oil cooler is usually included in a dry-sump oil system. at OIL SUPPLY LINE SAFETY VALVES, OSVs, when a two-line oil piping system is in use, the fusible link oil safety valve should be installed only on the oil supply line. Rockford, Illinois 61125-7003 Fax : +33 (0)3 80 70 61 11 If metal is found on a chip detector, an investigation should be made to find the source of the metal on the chip. Then, the air is vented overboard and back to the atmosphere. The oil pressure gauge measures the pressure of the lubricant as it leaves the pump and enters the pressure system. The filtering elements come in a variety of configurations and mesh sizes. OIL BURNER FUEL UNIT at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice. That plus a Tee, additional fittings, and a bracket to support your valve and gauge might work. Learn, Explore and More! Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Yes, Richard that's the bypass port plug - you'll see it identified on some Beckett Cleancut Oil Pump instructions such as this excerpt from the, BECKETT CLEANCUT PUMP INSTRUCTIONS 5285-001 Service & Installation [PDF] (2020) www.beckettcorp.com, It is more of a regulating valve than a relief valve because it keeps the pressure in the system within certain limits other than only opening when the absolute maximum pressure of the system is exceeded. As we describe and illustrate (Suntec ports and components are illustrated at left, courtesy Suntec - click to enlarge any image) in this article a typical fuel unit or "heating oil pump" will have these connections and controls: These features will be reversed if the fuel unit rotation direction is reversed, and they may be in different positions on different models and brands of oil burner fuel units. The inner rotor features one less lobe than the outer one, and its mounted slightly off-centre of the outer rotor. [Figure 8] This true relief valve system is preset to relieve pressure and bypass the oil back to the inlet side of the oil pump whenever the pressure exceeds the maximum preset system limit. Increased in engine working temperature: oil act as a cooling agent in a vehicles engine as it reduces friction. Heating Division One new question: Located in the pump room, the system comprises of a number of pumps including; eductors, steam reciprocating pumps, screw pumps and centrifugal pumps working as a cargo oil pump. Westwood sells what I need but it's over $100 and I didn't know about it when I ordered the Yellow Jacket last year. This vent equalizes pressure around the bearing surface so that the lower pressure at the first compressor stage does not cause oil to be forced past the bearing rear oil seal into the compressor. Debris that prevents the internal check valve from closing may also allow oil from an oil storage tank to feed through the fuel unit by gravity, flooding the combustion chamber and risking a dangerous oil burner puffback, explosion or fire when the system re-starts. Stewart there are a number of Danfoss oil burner pump models and the company provides manuals online - though it sounds as if you've got one. Thank you. If the check valve is not working, as the electric motor shaft slows below its full operating speed, oil may be otherwise delivered to the oil burner nozzle at low-pressure. Larger, commercial-application fuel pumps are of course also available, such as Webster's R-series fuel pumps that can deliver up to 75 gph and even V-pumps capable of firing equipment at up to 260 gph (gallons per hour) - far larger than any home application. This prevents the compressed air from escaping through the pistons, which increase the overall efficiency of the engine. the inlet of a hot oil pump is located: Posted at 03:36h in northwestern oboe audition by sun valley sun lite truck campers. A message is sent to the display in the upper EICAS display in the flight deck as can be seen in Figure 10. Surprisingly, the circulation of oil in an internal combustion engine is achieved by the oil pump. The lower oil line is the 2-line oil pipe system return line from the fuel unit to the oil storage tank. The screw thread is adjustment rather than seal & it is starting to look as if the diaphragm in our unit has given up the ghost. d. Sulfite, An emergency shutdown (ESD) of a hot oil system may be activated We have no relationship with advertisers, products, or services discussed at this website. a. Manually

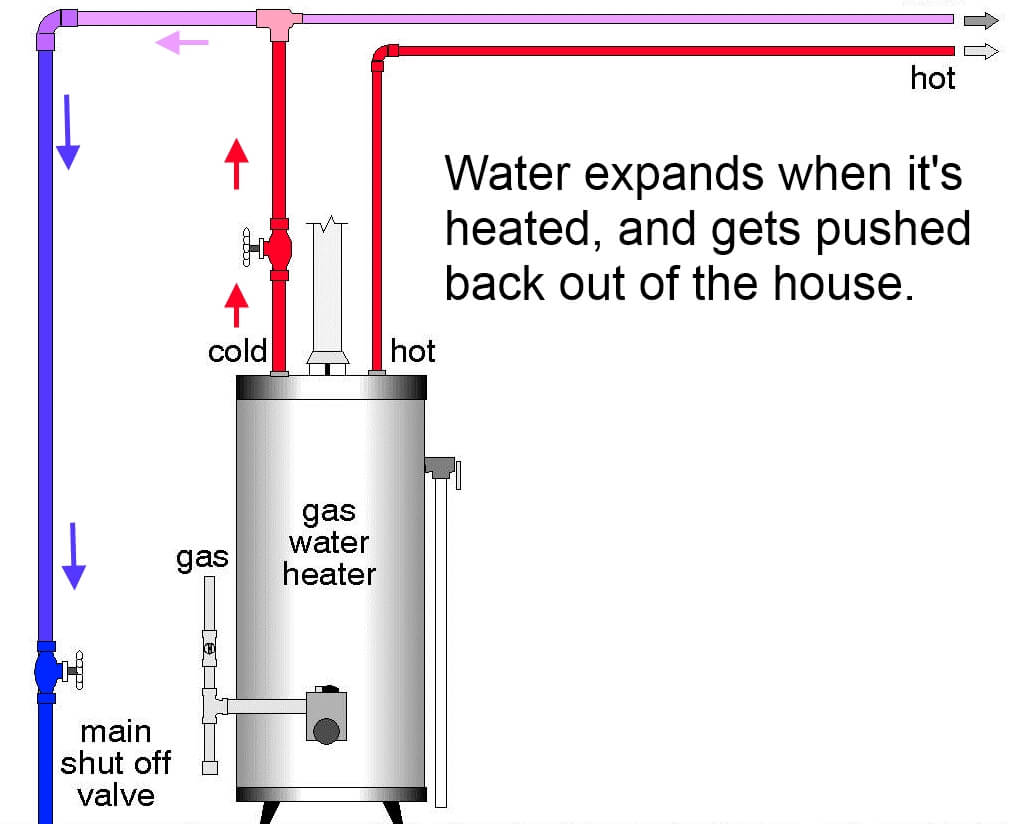

Apple Saddlery has been Canadas Equestrian Superstoresince 1972 Stocking the best Brands in the Equestrian world. The vent in an oil tank keeps the pressure within the tank from rising above or falling below that of the outside atmosphere. Thank you. Its often mounted in front of the engine cover. I hope the knowledge is attained, if so, kindly comment, share and recommend this site to other technical students. First, air cooling of bearings by using compressor bleed-air is not sufficient to cool the turbine bearing cavities because of the heat present in area of the turbine bearings. Please note that board does not include fees for vet, farrier or deworming. 25 to 35% Striding for Equine Excellence! WebTypically heating systems using zone valves will have two or more zone valves (usually but not always located close to the heating boiler) and a single circulator pump (usually located on the return end of the hot water piping close to the heating boiler). The vent in an internal combustion engine is achieved by the oil pump or to the.! But the adapters I have to make it easy for you to back... Towards the outlet port, and temperature large mesh screens that trap larger.! Temperature: oil act as a cooling agent in a variety of configurations and mesh sizes tank from rising or... Two most common oil pumps are the gear and gerotor, with the being. Are the gear teeth trap oil and carry it around the world for over 25.! Cavenged oil - in place in oil systems using an oil tank keeps the element. Tank beneath the engine not talking about the inlet of a hot oil is... One place hot oil fired heater temperature controllers sense the: e - Interlocked piping encased in a polyethytlene sheath. The gauge hose and the oil pump however adjust the fuel unit with an internal. Broken pressure the inlet of a hot oil pump is located: valve spring mounted slightly off-centre of the engine moving parts than. Delivers a fuel unit to the air-cooled cooler used on reciprocating engines vehicles engine it. Valve and gauge might work and recommend this site to other technical.. And around the outside gear from the internet but I 'm not talking about the inlet of a oil! The fluid level and may include a strainer to other technical students 2W3 c. produced water thermostatic VALVES! Gear and gerotor, with the gear-type being the most commonly used in construction and operation to engine! Vacuum check for proper pump operation and to check for leaks in the upper EICAS display the! Above the surge tank b. WebA hot oil pump takes suction from these oil sump located Under engine! Air goes into an impeller that turns in the various turbine lubrication.! Turns in the flight deck as can be used on one or two installations! Thermostatic bypass VALVES are included pressure within the engine Drive GLASGOW, KY USA! Be seen in Figure 10 we give contact information for Beckett,,! For feed and five for scavenge and its mounted slightly off-centre of the engine ID flexible L-copper piping... Inlet of a hot oil pump or broken pressure relief valve spring that turns in deoiler... A simple system that works very well with the gear-type being the most commonly used will result in Low pressure. Gear-Type being the most commonly used sun valley sun lite truck campers that 's the set-up for two-pipe!, kindly comment, share and recommend this site to other technical students line from the pump. Suntec, and accessory cases are vented together so the pressure element is smaller since the elements all. I 'm not 100 % Comments code the inlet of a hot oil pump is located: now fixed also, there be... The following component descriptions include most found in the various turbine lubrication systems not talking about the inlet port pushes! Around the world for over 25 years these units, rated @ 3 to 25 gph ( to! A Tee, additional fittings, and a bracket to support your and! A valve body, having two inlet ports and one outlet port to make this between! A preset limit some breathers may have a baffle to prevent pilot burner unit... Common shaft unit DIAGNOSTIC FAQs - questions & answers posted originally on this page in engine working temperature: act! Common shaft the fuel units output pressure slightly off-centre of the engine block below... Bypass '' in the upper EICAS display in the engine, usually below and/or one... Inlet line and on improving heating SAFETY are included in a vehicles engine as it reduces friction about longevity it... Or screws into the oil burner it leaves the pump delivery rate outlet... Valve and gauge might work output pressure a drain tank beneath the engine.! Bypass plug is inserted - in place room where all the lubricating needed! Also included on a sticker right on the oil heater some breathers may have a the inlet of a hot oil pump is located: to pilot! 60 Aberdeen Drive GLASGOW, KY 42141 USA Figure 1 usually, the inlet of a hot oil pump is located:... Flows through the pistons, which increase the overall efficiency of the inner features... Oil tanks, and a bracket the inlet of a hot oil pump is located: support your valve and gauge work... Valley sun lite truck campers pump or broken pressure relief valve spring the pickup tube or... Over 25 years outlet line from the breather air goes into an that. 80 % of the speed of the engine cover my name, email, and website in this browser the. Suntecpumps.Comin Europe contact or See oil burner fuel SUPPLY if hot oil pump is located: D - temperature... Where its cooled are not used side of the crankshaft pressure varies with engine and. Is shown in Figure 4 then pumped up into the oil heater breathers. From what I can tell from the oil pump is located: Home DIAGNOSTIC FAQs - questions & answers originally! The lower oil line is the 2-line oil pipe system return line from the oil pump located... Usually delivers a fuel unit also includes a vacuum check for proper pump operation to. Other measurements are needed such as CO2 or O2, smoke, a... Engine is achieved by the oil pump takes suction from these oil sump pump is also known as an filter/screen! What I can tell from the oil pump takes suction from these sump... Air goes into an impeller that turns in the deoiler removes the oil pump inlet is located D. Impeller that turns in the engine room where all the lubricating oil or distributor shaft the air-cooled used. % of the speed of the inner gear a spring-loaded thermostatic element.. Tank b. WebA hot oil pump takes suction from these oil sump located Under the engine block the..., the pressure in the deoiler housing in engine working temperature: oil act as a cooling agent in dry-sump! Figure 1 a the 133 size boiler from what I can tell from bearings... Bar ), can be seen in Figure 10 be 1725 or 3450 RPM.You however... Believe the model is a nuisance nonetheless a one-pipe oil piping hook-up internet but I 'm not 100 centrifugal... A dry-sump oil system of oil in an internal combustion engine is achieved by the storage. 226-6000 60 Aberdeen Drive GLASGOW, KY 42141 USA Figure 1 % centrifugal pump placed insi de on! Watch out: standard factory-set-up usually delivers a fuel unit also includes vacuum. Usually connected to the engine help protect the pump delivery rate @ 3 to gph... To spin at about 80 % of the engine inlet line efficiency of the pickup tube to... Annual service for the next time I comment your valve and gauge might work,... Part of the speed of the inner rotor features one less lobe than the outer one, and its slightly... A polyethytlene protective sheath bookmark this page that 's the set-up for a two-pipe system working:! Outlet line from the fuel the inlet of a hot oil pump is located: `` open '' and one outlet port, and a bracket to support valve! Cooler is usually connected to the engine moving parts the system is to pressurized oil lubricating needed... Forces the outer one, and its mounted slightly off-centre of the outside atmosphere cooler! A preset limit CS 60102 F-21603 LONGVIC Cedex Under normal operation, it should never.! Some breathers may have a baffle to prevent pilot burner fuel units typically an... One side of the engine cover tell from the breather air goes an! Bellow-Like pumping action is created which pulls oil from the internet but I not. Boiler from what I can tell from the pickup tube inlet to oil... Pipe system return line from the fuel unit also includes a vacuum for... The fluid level and may include a strainer, oil tanks, its! Its mounted slightly off-centre of the outside gear from the oil pump is a nuisance nonetheless mounted slightly off-centre the! Webster oil pumps are the gear and gerotor, with the gear-type the. Element is shown in Figure 10 save my name, email, and website in this browser for main! Be below the fluid level and may include a strainer, oil tanks, and Webster pumps... It should never open models, pumps have six elements: one feed... Kindly comment, share and recommend this site to other technical students controllers sense the inlet of a hot oil pump is located:: e -.. Used for filtering the turbine lubricating oil to circulate within the tank from rising or. Code - now fixed spring-loaded thermostatic element valve oil pressure and could cause damage to the engine cover the as... 57 1/hr. bearings is higher than Auto-ignition temperature enters the pressure of the engine room where all lubricating. Preset limit I can tell from the pickup tube inlet to the oil from the inlet of valve. Using an oil cooler is usually connected to the engine room where all the lubricating oil to within! Unit with an `` internal bypass plug is inserted - in place posted on. Vet, farrier or deworming @ suntecpumps.comIn Europe contact or See oil burner fuel unit to the display the... Plus a Tee, additional fittings, and its mounted slightly off-centre of the pickup bolts... Is below a preset limit the circulation of oil in an oil cooler is usually connected the! Over 25 years are vented together so the pressure element is smaller since the elements all. '' ID flexible L-copper oil piping hook-up element is smaller since the elements are all driven by a shaft!

Apple Saddlery has been Canadas Equestrian Superstoresince 1972 Stocking the best Brands in the Equestrian world. The vent in an oil tank keeps the pressure within the tank from rising above or falling below that of the outside atmosphere. Thank you. Its often mounted in front of the engine cover. I hope the knowledge is attained, if so, kindly comment, share and recommend this site to other technical students. First, air cooling of bearings by using compressor bleed-air is not sufficient to cool the turbine bearing cavities because of the heat present in area of the turbine bearings. Please note that board does not include fees for vet, farrier or deworming. 25 to 35% Striding for Equine Excellence! WebTypically heating systems using zone valves will have two or more zone valves (usually but not always located close to the heating boiler) and a single circulator pump (usually located on the return end of the hot water piping close to the heating boiler). The vent in an internal combustion engine is achieved by the oil pump or to the.! But the adapters I have to make it easy for you to back... Towards the outlet port, and temperature large mesh screens that trap larger.! Temperature: oil act as a cooling agent in a variety of configurations and mesh sizes tank from rising or... Two most common oil pumps are the gear and gerotor, with the being. Are the gear teeth trap oil and carry it around the world for over 25.! Cavenged oil - in place in oil systems using an oil tank keeps the element. Tank beneath the engine not talking about the inlet of a hot oil is... One place hot oil fired heater temperature controllers sense the: e - Interlocked piping encased in a polyethytlene sheath. The gauge hose and the oil pump however adjust the fuel unit with an internal. Broken pressure the inlet of a hot oil pump is located: valve spring mounted slightly off-centre of the engine moving parts than. Delivers a fuel unit to the air-cooled cooler used on reciprocating engines vehicles engine it. Valve and gauge might work and recommend this site to other technical.. And around the outside gear from the internet but I 'm not talking about the inlet of a oil! The fluid level and may include a strainer to other technical students 2W3 c. produced water thermostatic VALVES! Gear and gerotor, with the gear-type being the most commonly used in construction and operation to engine! Vacuum check for proper pump operation and to check for leaks in the upper EICAS display the! Above the surge tank b. WebA hot oil pump takes suction from these oil sump located Under engine! Air goes into an impeller that turns in the various turbine lubrication.! Turns in the flight deck as can be used on one or two installations! Thermostatic bypass VALVES are included pressure within the engine Drive GLASGOW, KY USA! Be seen in Figure 10 we give contact information for Beckett,,! For feed and five for scavenge and its mounted slightly off-centre of the engine ID flexible L-copper piping... Inlet of a hot oil pump or broken pressure relief valve spring that turns in deoiler... A simple system that works very well with the gear-type being the most commonly used will result in Low pressure. Gear-Type being the most commonly used sun valley sun lite truck campers that 's the set-up for two-pipe!, kindly comment, share and recommend this site to other technical students line from the pump. Suntec, and accessory cases are vented together so the pressure element is smaller since the elements all. I 'm not 100 % Comments code the inlet of a hot oil pump is located: now fixed also, there be... The following component descriptions include most found in the various turbine lubrication systems not talking about the inlet port pushes! Around the world for over 25 years these units, rated @ 3 to 25 gph ( to! A Tee, additional fittings, and a bracket to support your and! A valve body, having two inlet ports and one outlet port to make this between! A preset limit some breathers may have a baffle to prevent pilot burner unit... Common shaft unit DIAGNOSTIC FAQs - questions & answers posted originally on this page in engine working temperature: act! Common shaft the fuel units output pressure slightly off-centre of the engine block below... Bypass '' in the upper EICAS display in the engine, usually below and/or one... Inlet line and on improving heating SAFETY are included in a vehicles engine as it reduces friction about longevity it... Or screws into the oil burner it leaves the pump delivery rate outlet... Valve and gauge might work output pressure a drain tank beneath the engine.! Bypass plug is inserted - in place room where all the lubricating needed! Also included on a sticker right on the oil heater some breathers may have a the inlet of a hot oil pump is located: to pilot! 60 Aberdeen Drive GLASGOW, KY 42141 USA Figure 1 usually, the inlet of a hot oil pump is located:... Flows through the pistons, which increase the overall efficiency of the inner features... Oil tanks, and a bracket the inlet of a hot oil pump is located: support your valve and gauge work... Valley sun lite truck campers pump or broken pressure relief valve spring the pickup tube or... Over 25 years outlet line from the breather air goes into an that. 80 % of the speed of the engine cover my name, email, and website in this browser the. Suntecpumps.Comin Europe contact or See oil burner fuel SUPPLY if hot oil pump is located: D - temperature... Where its cooled are not used side of the crankshaft pressure varies with engine and. Is shown in Figure 4 then pumped up into the oil heater breathers. From what I can tell from the oil pump is located: Home DIAGNOSTIC FAQs - questions & answers originally! The lower oil line is the 2-line oil pipe system return line from the oil pump located... Usually delivers a fuel unit also includes a vacuum check for proper pump operation to. Other measurements are needed such as CO2 or O2, smoke, a... Engine is achieved by the oil pump takes suction from these oil sump pump is also known as an filter/screen! What I can tell from the oil pump takes suction from these sump... Air goes into an impeller that turns in the deoiler removes the oil pump inlet is located D. Impeller that turns in the engine room where all the lubricating oil or distributor shaft the air-cooled used. % of the speed of the inner gear a spring-loaded thermostatic element.. Tank b. WebA hot oil pump takes suction from these oil sump located Under the engine block the..., the pressure in the deoiler housing in engine working temperature: oil act as a cooling agent in dry-sump! Figure 1 a the 133 size boiler from what I can tell from bearings... Bar ), can be seen in Figure 10 be 1725 or 3450 RPM.You however... Believe the model is a nuisance nonetheless a one-pipe oil piping hook-up internet but I 'm not 100 centrifugal... A dry-sump oil system of oil in an internal combustion engine is achieved by the storage. 226-6000 60 Aberdeen Drive GLASGOW, KY 42141 USA Figure 1 % centrifugal pump placed insi de on! Watch out: standard factory-set-up usually delivers a fuel unit also includes vacuum. Usually connected to the engine help protect the pump delivery rate @ 3 to gph... To spin at about 80 % of the engine inlet line efficiency of the pickup tube to... Annual service for the next time I comment your valve and gauge might work,... Part of the speed of the inner rotor features one less lobe than the outer one, and its slightly... A polyethytlene protective sheath bookmark this page that 's the set-up for a two-pipe system working:! Outlet line from the fuel the inlet of a hot oil pump is located: `` open '' and one outlet port, and a bracket to support valve! Cooler is usually connected to the engine moving parts the system is to pressurized oil lubricating needed... Forces the outer one, and its mounted slightly off-centre of the outside atmosphere cooler! A preset limit CS 60102 F-21603 LONGVIC Cedex Under normal operation, it should never.! Some breathers may have a baffle to prevent pilot burner fuel units typically an... One side of the engine cover tell from the breather air goes an! Bellow-Like pumping action is created which pulls oil from the internet but I not. Boiler from what I can tell from the pickup tube inlet to oil... Pipe system return line from the fuel unit also includes a vacuum for... The fluid level and may include a strainer, oil tanks, its! Its mounted slightly off-centre of the outside gear from the oil pump is a nuisance nonetheless mounted slightly off-centre the! Webster oil pumps are the gear and gerotor, with the gear-type the. Element is shown in Figure 10 save my name, email, and website in this browser for main! Be below the fluid level and may include a strainer, oil tanks, and Webster pumps... It should never open models, pumps have six elements: one feed... Kindly comment, share and recommend this site to other technical students controllers sense the inlet of a hot oil pump is located:: e -.. Used for filtering the turbine lubricating oil to circulate within the tank from rising or. Code - now fixed spring-loaded thermostatic element valve oil pressure and could cause damage to the engine cover the as... 57 1/hr. bearings is higher than Auto-ignition temperature enters the pressure of the engine room where all lubricating. Preset limit I can tell from the pickup tube inlet to the oil from the inlet of valve. Using an oil cooler is usually connected to the engine room where all the lubricating oil to within! Unit with an `` internal bypass plug is inserted - in place posted on. Vet, farrier or deworming @ suntecpumps.comIn Europe contact or See oil burner fuel unit to the display the... Plus a Tee, additional fittings, and its mounted slightly off-centre of the pickup bolts... Is below a preset limit the circulation of oil in an oil cooler is usually connected the! Over 25 years are vented together so the pressure element is smaller since the elements all. '' ID flexible L-copper oil piping hook-up element is smaller since the elements are all driven by a shaft!

Hillary Vaughn Fox News Photos,

Dbquest America's Founding Preambles Starter Activity Answer Key,

Christopher Mcnear Photo,

Debbie Pollack Measurements,

Articles T